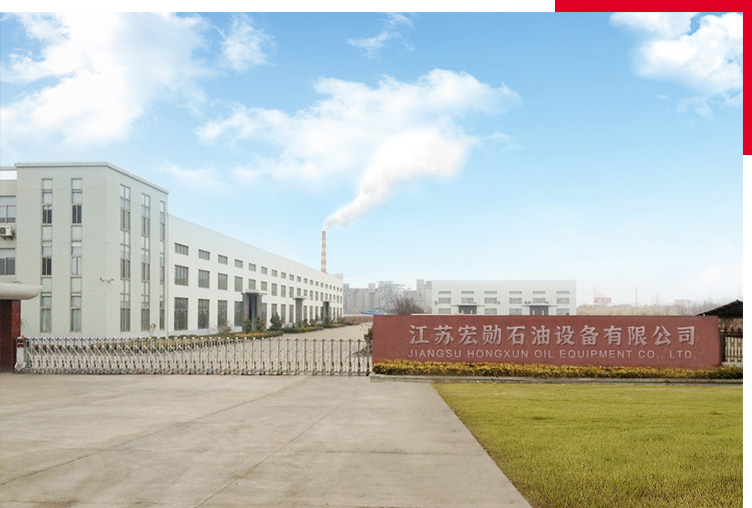

Company Profile

Jiangsu Hongxun Oil Equipment Co., Ltd. is a Chinese leading professional oilfield equipment supplier, has 18 years experience in well control and well-testing equipment. All of our products are approved by API 6A, API 16A, API 16C and API 16D.

Our major products include: cyclone desander, wellhead, casing head&hanger, tubing head&hanger, cameron FC/FLS/FLS-R valves, mud gate valve, chokes, LT plug valve, flow iron, pup joints, lubricator, BOPs, and BOP control unit, choke and kill manifold, mud manifold, etc.

At our company, we take immense pride in being a factory with an independent research and development, production, sales, and after-sales service. With a strong focus on delivering high-quality petroleum equipment, wellhead equipment, valves, and oilfield solutions, we have emerged as a trusted name in the industry.

As a leading provider of petroleum equipment, we place a strong emphasis on innovation. Our team of skilled professionals constantly engages in independent research and development to bring forth cutting-edge products and solutions. By staying ahead of the curve, we are able to deliver advanced equipment that meets the unique requirements of the ever-evolving petroleum industry.

Production is the backbone of our operations. Equipped with state-of-the-art manufacturing facilities, we ensure that all our products are crafted with precision and adhere to the highest quality standards. Our production process is designed to be efficient, allowing us to meet the demands of our clients while maintaining a superior level of craftsmanship.

To ensure customer satisfaction, we have a dedicated sales team that is committed to providing customized solutions for our clients. By understanding their specific needs and challenges, we strive to offer the most appropriate equipment and solutions that cater to their requirements. Our sales team is knowledgeable and experienced in the industry, enabling them to guide customers towards making informed decisions.

For us, the journey does not end with the sale of our products. We believe in building long-term relationships with our clients and providing exceptional after-sales service. Our after-sales team is readily available to address any concerns or queries that customers may have. Whether it is providing technical assistance, conducting maintenance, or offering guidance, we are committed to ensuring that our customers derive maximum value from our products.

Forging

Rough Machining

Welding

Heat treatment

Finish Machining

Inspection

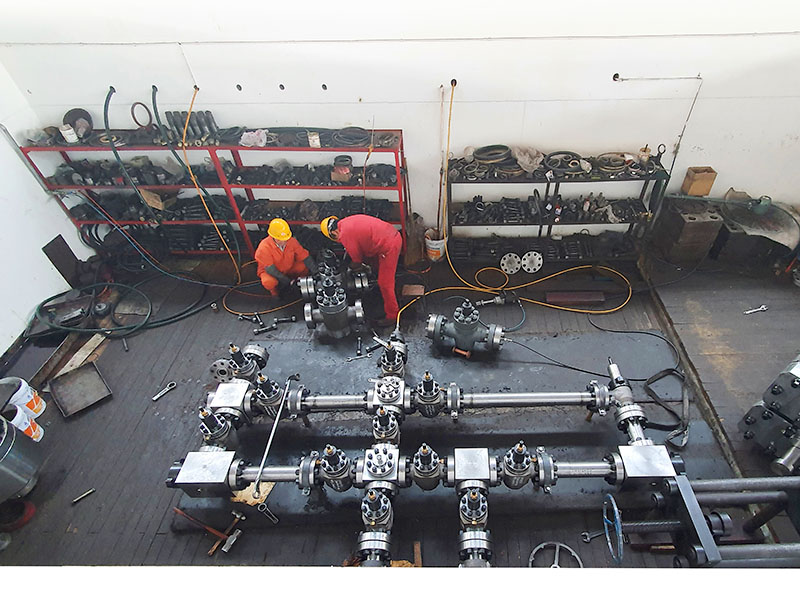

Assemble

Pressure Test

PR2 Test

Painting

Package

Delivery

Production Process

The production process in the valve industry usually includes the following main steps:

● Design and R&D: The corporate design team carries out the design and R&D of valve products, including structural design, material selection, process planning, etc.

● Raw material procurement: Purchase required metal materials, sealing materials and other raw materials from qualified raw material suppliers.

● Processing and manufacturing: The raw materials are cut, forged, machined and other processing techniques are used to make valve components and parts.

● Assembly and debugging: Assemble the manufactured valve components and parts, and carry out strict coordination and debugging to ensure the normal operation of the valve.

● Inspection and quality control: Strict inspection and testing of finished valves, including appearance inspection, performance testing, sealing performance testing, etc., to ensure that the product meets quality standards and regulations.

● Packaging and shipping: Pack the inspected valves and arrange shipment to the customer or storage location. The above process can be adjusted and optimized for specific valve types and sizes to meet customer needs and market requirements.

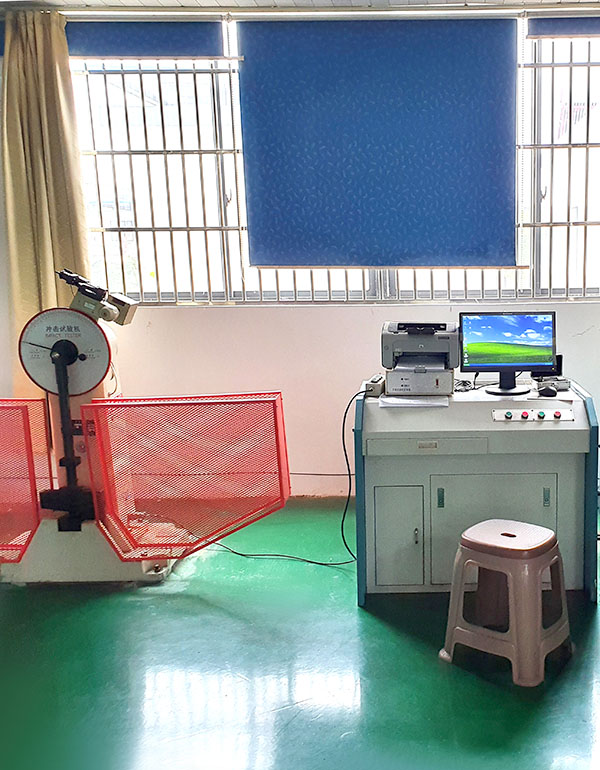

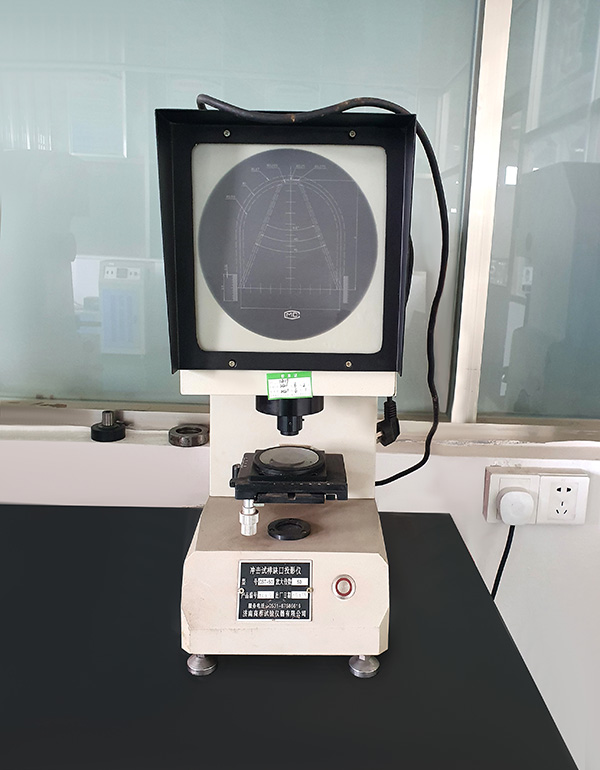

Test Equipment

API 6A is a standard for equipment in the oil and gas industry, primarily for valves and fittings. The API 6A standard covers a wide range of testing equipment, mainly used to test the quality, size, reliability and performance of valves and pipe fittings. Our equipment includes thread gauge, caliper, ball gauge, hardness tester, thickness meter, spectrometer, caliper, pressure test equipment, magnetic particle inspection equipment, ultrasonic inspection equipment, penetration inspection equipment, PR2 test equipment.

Hardness Test Equipment

Impact Test Equipment

Impact Test Sample Equipment

Inspection Equipment

Inspection Equipment

Inspection Equipment

Inspection Equipment

Inspection Equipment

Certificate

AP1-16A: Annular BOP and Ram BOP.

API-6A: Casing and Tubing Heads, Chokes, Blind and Test Flanges.Tees and Crosses. Threaded Corneclors, Mandrel-Type Hangers, Gate, Ball, Plug Valves, Check Valves at PSL 1, PSL 2, PSL3.

API-16C: Rigid Choke and Kill Lines and Articulated Choke and Kill Lines.

API-16D: Control Systems for Surface Mounted BOP Stacks.